Together, we create quality plastic solutions

Certified staff

When welding plastic sheets, pipes or

When welding plastic sheets, pipes, or tanks, a wide range of requirements must be met, including pressure, temperature, and time, depending on the material type and thickness. These requirements help ensure that the welds are performed correctly and remain leak-proof.

We only employ certified technicians. Our technicians have completed one or more of the following courses, which set requirements for both practical and theoretical skills:

- B (Basic Certificate)

- USME (Advanced training for butt, socket, and electrofusion welding)

- UVE (Advanced training for hot air and extruder welding)

- GAS

Additionally, we place great emphasis on continuous training for all our employees, ensuring they stay up to date with the latest knowledge and have the right skills to carry out their tasks effectively.

Quality standards and tests

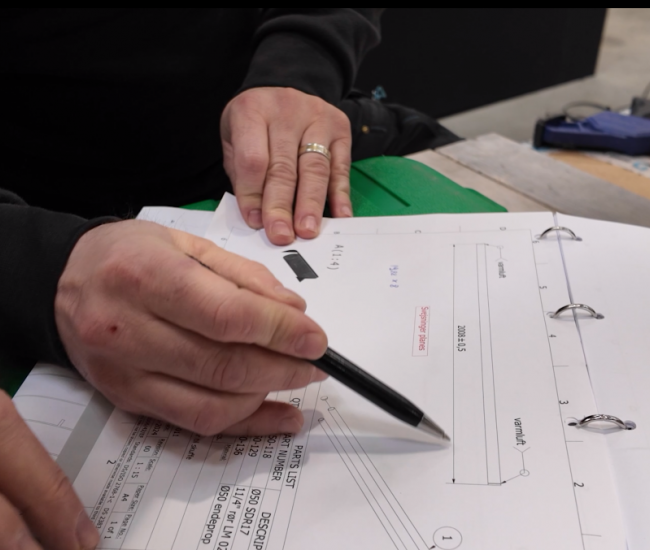

We are with you from the planning phase to the handover of the finished product. With our internal quality standards, we maintain a high level of quality and ensure that the product meets your expectations and requirements.

- Final product drawings and designs are always sent to the customer for final approval before production begins.

- As part of our quality procedures, we conduct an internal review of the drawings before the solution is sent to production to ensure quality.

- All products are tested before delivery. Depending on the project, as well as the product’s purpose and material, they will undergo spark testing, pressure testing, visual inspection, and/or water testing.

- Additionally, all welds are visually inspected by the project manager and foreman.

Official approvals for plastic products

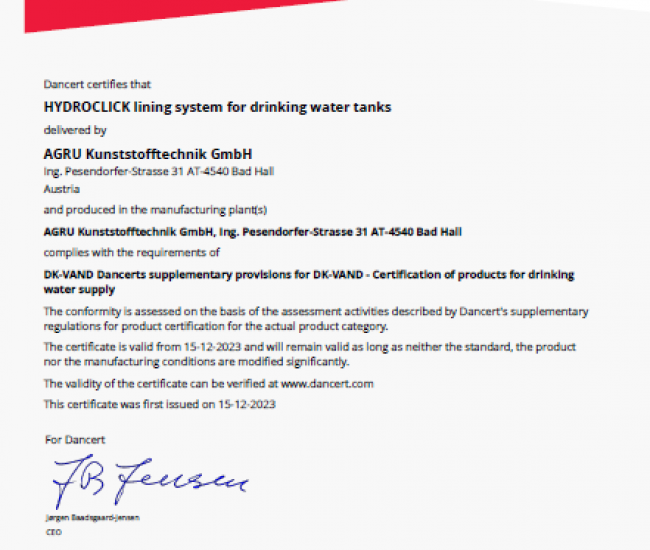

Working with our plastics suppliers, we have access to a wide range of products that comply with the standards set in Denmark under the DK-VAND and GDV regulations. We also have a number of plastic products for water plants that are additionally KIWA and DVGW-certified. These certificates are recognised in Denmark and many other European countries.

It is important to us that we use materials that offer the customer the best solution, while complying with all legal requirements. We have customers with special requirements regarding plastic materials, and fortunately with our wide supplier network this poses no problems.

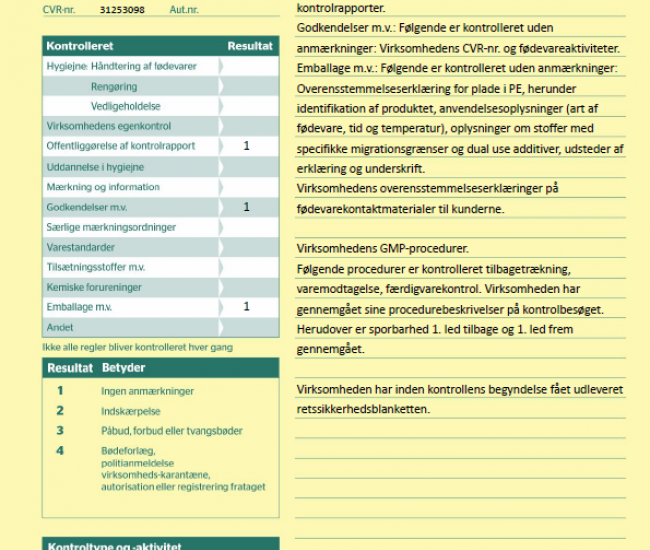

Food-Grade approved production

Dansk Plast is approved by the Danish Veterinary and Food Administration to store, handle, and manufacture products using food-grade plastic materials. With this approval, we are well-equipped to meet the needs of our customers in the food industry and ensure that our products comply with all applicable requirements and standards.

Our internal quality standards allow us to maintain high quality

From Idea to Finished Product – Together, We Create the Best Solution

You know what your product is meant for – and we have the expertise to make it a reality.

That’s why every project begins with a thorough assessment of your needs. Together, we define the requirements the product must meet, the conditions it will be exposed to, and the most suitable materials.

With this insight, we develop a well-thought-out plan that ensures high quality in both development and production. For us, it’s not just plastic – it’s the right plastic solution tailored to your specific needs.

Plastic is not just plastic

Plastic comes in many variations, each with its own unique durability, chemical resistance, and ability to withstand harsh weather conditions. That’s why choosing the right type of plastic is crucial for the quality and lifespan of your product.

At Dansk Plast, we understand that the optimal plastic solution depends on both application and environment. We ensure high quality by carefully selecting materials that meet specific requirements—whether it involves contact with special liquids, extreme temperatures, or outdoor exposure.

Through close collaboration and in-depth expertise, we deliver customized plastic constructions that match your needs—with a focus on durability, functionality, and safety.