From ongoing production to custom design and complete systems

Modern production facilities and expert advice

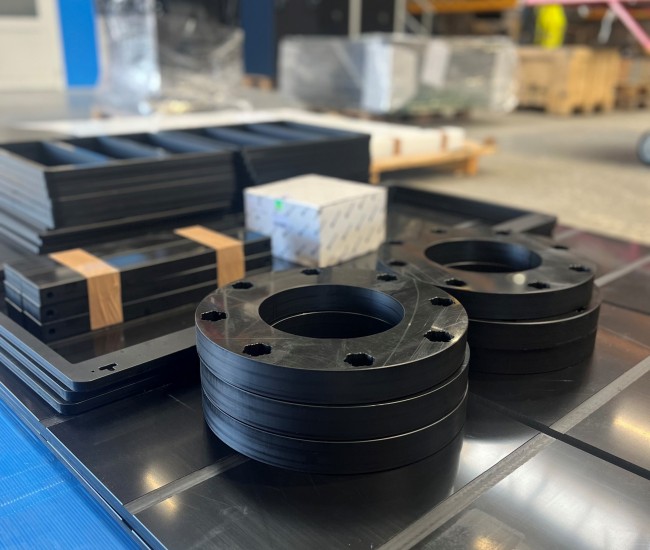

At our location in Esbjerg, we have modern production facilities where we can assist you – whether you are in the design phase or have finished production drawings and are looking for a reliable production partner.

We have invested in a range of large machines and continuously work to develop our production capacity with the latest technologies. As a result, we are often involved as a sparring partner in various projects.

With our broad expertise, we know what is cost-effective – and what is not. We always provide competent advice before starting production to ensure you get the optimal solution.

From prototype to finished product

Do you need a prototype in the early stages of a project? We have the right expertise in plastic design and construction, and can not only assist with production but also act as a sparring partner in the development of your prototype.

Additionally, we collaborate with customers who require custom-made products in very small batches. Whether you need advice in the development process or simply require a reliable production partner, we are here to help. No task is too small or too large for us.

From design to finished product – with a focus on quality

With our in-house production in Esbjerg, we can follow your products all the way from design to finished product. This ensures consistent, high quality as we closely monitor and adhere to all quality procedures from start to finish.

In many cases, our collaboration starts even before the actual production in what we call production maturation. Here, we contribute our expertise in welding and plastics to help find the optimal materials and welding methods. This ensures efficient production and a consistent final product of high quality.

Learn more about our quality requirements and certifications.